UV Printer vs DTG Printer: Which is Right for Your Business?

Complete comparison of UV printers and DTG printers. Learn which technology is best for your business based on materials, costs, print quality, and profit potential.

Quick Answer: Choose a UV printer if you want to print on hard surfaces (glass, metal, wood, plastic, phone cases, signs) and diversify your product offerings. Choose a DTG printer if your focus is custom apparel (t-shirts, hoodies, bags) on cotton fabrics. UV printers offer greater versatility and higher profit margins across more industries, while DTG excels specifically in garment decoration.

Choosing between a UV printer and a DTG (Direct-to-Garment) printer is one of the most important decisions you’ll make when starting or expanding a custom printing business. Both technologies offer excellent print quality and profit potential, but they serve fundamentally different markets and applications.

This comprehensive comparison guide breaks down everything you need to know — from material compatibility and print costs to maintenance requirements and ROI potential — so you can make the right investment for your business goals.

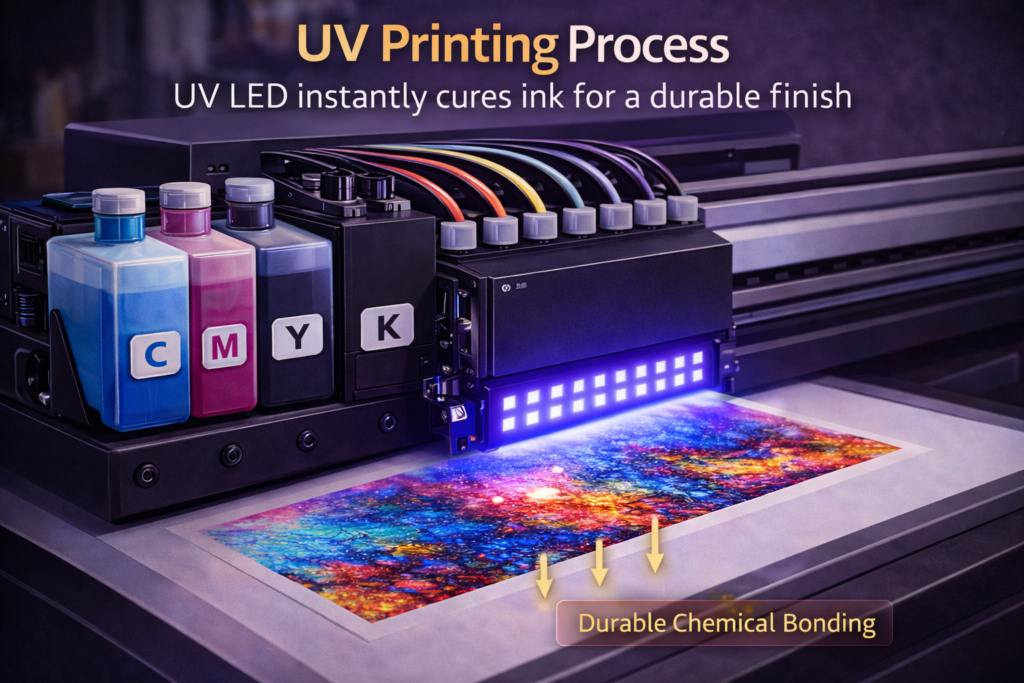

What is UV Printing?

A UV printer uses ultraviolet light to instantly cure (dry) specially formulated UV inks as they’re printed onto virtually any surface. Unlike traditional inkjet printing that relies on evaporation or absorption, UV curing creates an immediate chemical bond between the ink and substrate.

How UV Printing Works

- Design Preparation: Your artwork is processed through RIP software that manages color profiles, white ink generation, and print optimization.

- Ink Application: The printhead deposits UV-curable inks (CMYK + White + Varnish) onto the substrate surface.

- Instant Curing: UV LED lamps immediately cure the ink as it’s applied, creating a durable, scratch-resistant finish.

- Ready to Use: Products are finished immediately — no drying time, no post-processing required.

What Can UV Printers Print On?

UV printing’s greatest strength is its material versatility. You can print on virtually any hard or semi-rigid surface:

- Rigid materials: Acrylic, glass, wood, metal, ceramic, stone, MDF

- Plastics: PVC, ABS, polycarbonate, polystyrene, corrugated plastic

- Consumer products: Phone cases, promotional items, awards, trophies, signs

- Packaging: Boxes, bottles, jars, tubes, gift packaging

- Cylindrical items: Bottles, tumblers, cups, pens (with rotary attachment)

- Flexible materials: Leather, faux leather, some specialty fabrics, vinyl

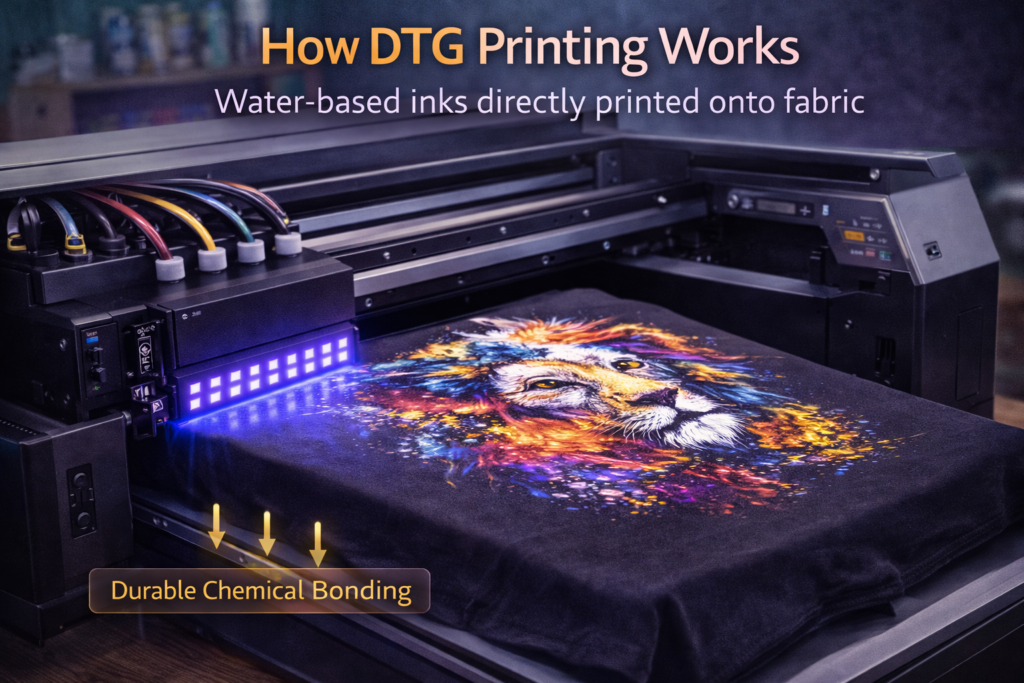

What is DTG Printing?

DTG (Direct-to-Garment) printing is a digital printing method that sprays water-based textile inks directly onto fabric, primarily cotton and cotton-blend garments. It works similarly to an inkjet printer but is specifically designed for textiles.

How DTG Printing Works

- Pretreatment (for dark garments): A pretreatment solution is applied to help white ink adhere properly and maintain vibrancy.

- Garment Loading: The garment is placed on a platen and positioned under the printhead.

- Ink Application: Water-based textile inks are sprayed directly onto the fabric (white underbase first for dark garments, then CMYK colors).

- Heat Curing: The printed garment is heat-pressed or conveyor-cured to bond the ink permanently to the fabric fibers.

What Can DTG Printers Print On?

DTG printing is specifically designed for textiles:

- Cotton garments: T-shirts, hoodies, sweatshirts (best results on 100% cotton)

- Cotton blends: 50/50 cotton-polyester blends (results vary)

- Canvas: Tote bags, canvas shoes, canvas art

- Denim: Jeans, denim jackets (with proper preparation)

- Other natural fibers: Linen, silk (limited applications)

Important: DTG does NOT work well on polyester or synthetic fabrics. For polyester, sublimation printing is the preferred method.

UV Printer vs DTG Printer: Head-to-Head Comparison

| Factor | UV Printer | DTG Printer |

| Primary Materials | Hard surfaces: glass, metal, wood, plastic, acrylic, ceramic | Textiles: cotton, cotton blends, canvas |

| Ink Type | UV-curable inks (CMYK + White + Varnish) | Water-based textile pigment inks |

| Curing Method | UV LED lamps (instant curing) | Heat press or conveyor dryer |

| Pretreatment Required | No (surface cleaning only) | Yes (especially for dark garments) |

| Print Speed | Fast (instant curing, no post-processing) | Moderate (requires curing time) |

| Equipment Price | $3,000 – $50,000+ | $3,000 – $30,000+ |

| Print Durability | Excellent (scratch/fade/water resistant) | Good (20-50+ washes with proper care) |

| Print Feel | Raised, textured finish (sits on surface) | Soft, breathable (ink absorbs into fabric) |

| Market Versatility | Very High (multiple industries) | Limited (apparel only) |

Cost Comparison: UV Printing vs DTG Printing

Understanding the true cost of each technology helps you calculate ROI and set profitable pricing. Let’s break down the numbers:

Initial Equipment Investment

| Equipment | UV Printer | DTG Printer |

| Entry-Level Printer | $3,000 – $8,000 | $3,000 – $6,000 |

| Mid-Range Printer | $8,000 – $20,000 | $8,000 – $15,000 |

| Production Printer | $20,000 – $50,000+ | $15,000 – $30,000+ |

| Additional Equipment | Rotary attachment ($500-2,000) | Pretreat machine ($2,000-5,000), Heat press ($500-2,000) |

Cost Per Print Comparison

| Cost Factor | UV Printer | DTG Printer |

| Ink Cost (per print) | $0.30 – $1.50 | $0.50 – $3.50 |

| Pretreatment | $0 (not required) | $0.25 – $0.50/garment |

| White Ink (dark substrates) | +$0.50 – $1.00 | +$1.00 – $3.00 |

| Typical Total Cost | $0.30 – $2.50/print | $2.50 – $5.00/print |

Cost Winner: UV Printing — Lower ink costs, no pretreatment required, and faster production times result in significantly lower cost per print and higher profit margins.

Pros and Cons: UV Printer vs DTG Printer

UV Printer Advantages

- Unmatched material versatility: Print on virtually any hard surface — glass, metal, wood, plastic, ceramic, and more

- Instant curing: No drying time, products ready immediately

- No pretreatment needed: Simpler workflow, lower consumable costs

- Superior durability: Scratch-resistant, waterproof, fade-resistant prints

- Special effects: Varnish layer enables gloss, matte, raised textures, and 3D effects

- Higher profit potential: Broader market access and premium product pricing

- Lower ink consumption: More efficient ink usage compared to DTG

UV Printer Disadvantages

- Not ideal for apparel: UV ink sits on fabric surface rather than absorbing — less breathable, stiffer hand feel

- Higher initial cost: Production-level UV printers cost more than entry DTG systems

- White ink maintenance: Requires circulation systems to prevent settling (though this is automated on quality machines)

DTG Printer Advantages

- Soft hand feel: Ink absorbs into fabric fibers for a breathable, comfortable print

- Best for cotton apparel: Specifically designed for t-shirts, hoodies, and cotton garments

- Photo-quality detail: Excellent for complex, full-color designs with gradients

- No minimum orders: Economical for single-piece and small-batch production

- Established technology: Well-documented processes and widespread support

DTG Printer Disadvantages

- Limited to textiles: Cannot print on hard surfaces, plastics, or non-fabric materials

- Pretreatment required: Dark garments need pretreatment spray, adding time and cost

- Higher ink costs: Textile inks are expensive, especially white ink for dark shirts

- Polyester limitations: Poor results on synthetic fabrics — requires sublimation instead

- Frequent maintenance: Daily head cleaning required to prevent clogs

- Wash durability concerns: Prints may fade after 20-50 washes without proper curing

Best Applications for Each Technology

Best Applications for UV Printing

- Signage & displays: Indoor/outdoor signs, POP displays, wayfinding

- Promotional products: Pens, USB drives, keychains, corporate gifts

- Phone cases & tech accessories: Custom cases, laptop covers, tablet cases

- Awards & recognition: Plaques, trophies, certificates, name plates

- Home décor: Photo panels, wall art, decorative tiles

- Packaging & labels: Boxes, bottles, jars, luxury packaging

- Industrial printing: Control panels, equipment labels, nameplates

- Drinkware: Tumblers, bottles, mugs, glasses (with rotary attachment)

Best Applications for DTG Printing

- Custom t-shirts: Single orders, small batches, on-demand printing

- Fashion apparel: Streetwear brands, boutique clothing lines

- Hoodies & sweatshirts: Custom outerwear with detailed designs

- Canvas bags: Tote bags, canvas accessories

- Event merchandise: Concerts, festivals, corporate events

- Print-on-demand: E-commerce fulfillment, dropshipping

Which Printer Should You Choose?

Choose a UV Printer If…

- You want to serve multiple industries and markets

- You’re interested in promotional products, signage, awards, or packaging

- You need to print on hard surfaces like glass, metal, wood, or plastic

- You want faster production times with instant curing

- You prefer a simpler workflow without pretreatment

- You want to maximize profit margins with diverse offerings

- You’re building a business with long-term scalability

Choose a DTG Printer If…

- Your primary focus is custom apparel (t-shirts, hoodies)

- You’re starting a clothing brand or fashion line

- You need soft, breathable prints that feel natural on fabric

- Your customers primarily order cotton garments

- You’re doing print-on-demand or e-commerce fulfillment

- You want a lower initial investment to test the market

The Verdict: UV Printer Offers Greater Business Potential

While both technologies have their place, UV printing offers significantly greater business potential for most entrepreneurs. Here’s why:

- Higher versatility = more revenue streams: A single UV printer can serve signage companies, gift shops, promotional product distributors, photographers, and more. DTG is limited to apparel.

- Better profit margins: Lower ink costs, no pretreatment, and faster production times result in higher profits per product.

- Less competition in many niches: The custom t-shirt market is saturated. UV printing opens doors to less competitive, higher-margin markets like awards, signage, and industrial printing.

- Growing demand: Personalization trends are driving demand across all product categories, and UV printers can capitalize on this across multiple industries.

That said, if your passion is fashion and your business model centers on custom apparel, a DTG printer is the right specialized tool for that job. Many successful print shops eventually own both technologies to serve the widest possible market.

Ready to explore UV printing for your business? Browse MTuTech’s complete UV printer lineup to find the right machine for your goals.

Frequently Asked Questions

Can a UV printer print on fabric?

Technically yes, but it’s not recommended for garments. UV ink sits on top of fabric rather than absorbing into fibers, resulting in a stiffer, less breathable feel. For apparel, DTG or DTF printing is preferred. UV printing works well on leather, canvas, and other rigid or semi-rigid materials.

Can a DTG printer print on hard surfaces?

No. DTG printers use water-based textile inks that require absorbent materials like cotton fabric. They cannot print on glass, metal, plastic, or other hard surfaces. For hard materials, you need a UV printer.

Which is more profitable: UV printing or DTG?

UV printing generally offers higher profit potential due to lower per-unit costs, broader market access, and less competition in many product niches. However, profitability ultimately depends on your business model, target market, and how effectively you serve your customers.

Can I print on polyester with DTG?

DTG does not work well on 100% polyester. The water-based inks don’t bond properly to synthetic fibers, resulting in poor wash durability and color vibrancy. For polyester, sublimation printing is the preferred technology.

How long do UV prints last compared to DTG?

UV prints on hard surfaces can last 3-7+ years outdoors and indefinitely indoors when properly applied. DTG prints on garments typically last 20-50+ washes with proper curing. Both technologies produce durable results when done correctly.

Do I need both a UV printer and DTG printer?

It depends on your business model. If you want to offer both custom apparel AND hard-surface products (signs, awards, promotional items), having both technologies gives you maximum market coverage. Many print shops start with one and add the other as they grow.

Which requires more maintenance: UV or DTG?

DTG printers typically require more daily maintenance, including head cleaning and pretreatment of garments. UV printers with white ink circulation systems require less frequent intervention. Both technologies need regular care for optimal performance, but UV printers with modern automation features tend to be more forgiving.

What about UV DTF vs DTG? UV DTF (Direct-to-Film) creates transfers for hard surfaces — it’s related to UV printing technology. Regular DTF (also Direct-to-Film) creates heat transfers for fabrics — it’s a competitor to DTG. UV DTF is for hard surfaces like tumblers and phone cases; DTG and DTF are for textiles