UV Printer Ink Cost: Complete Breakdown & Savings Tips

Complete guide to UV printer ink costs in 2025. Learn how much CMYK, white, and varnish inks cost per liter, calculate your cost per print, and discover proven strategies to reduce ink expenses by 15-30%.

Quick Answer: UV printer ink typically costs $50-200 per liter depending on color, quality, and brand. CMYK inks range from $50-100/liter, white ink costs $80-150/liter, and varnish runs $60-120/liter. At average consumption rates of 8-15ml per square meter, your ink cost per print works out to roughly $0.30-1.00 per square meter — making UV printing one of the most cost-effective professional printing methods available.

Understanding your ink costs is essential for running a profitable UV printing business. Ink is your largest ongoing consumable expense — and it’s also the area where smart decisions can save you thousands of dollars per year.

In this comprehensive guide, we’ll break down exactly what UV printer ink costs, how to calculate your true cost per print, and proven strategies to reduce your ink expenses without sacrificing quality. Whether you’re running a small custom products business or a high-volume production shop, this guide will help you optimize your ink spending.

UV Printer Ink Pricing: 2025 Market Overview

UV ink prices vary significantly based on several factors including ink type, brand, quality grade, and purchase volume. Here’s what you can expect to pay in the current market:

| Ink Type | Budget Range | Premium Range | OEM/Brand |

| Cyan (C) | $50-70/L | $80-120/L | $150-200/L |

| Magenta (M) | $50-70/L | $80-120/L | $150-200/L |

| Yellow (Y) | $50-70/L | $80-120/L | $150-200/L |

| Black (K) | $50-70/L | $80-120/L | $150-200/L |

| White (W) | $80-100/L | $120-150/L | $180-250/L |

| Varnish/Gloss | $60-80/L | $90-120/L | $140-180/L |

| Light Cyan (LC) | $55-75/L | $85-125/L | $160-210/L |

| Light Magenta (LM) | $55-75/L | $85-125/L | $160-210/L |

Key Insight: White ink is consistently the most expensive UV ink due to the titanium dioxide pigments required for opacity. If your business relies heavily on white ink (printing on dark or transparent substrates), this will significantly impact your costs.

Understanding Different UV Ink Types

CMYK Process Inks

CMYK (Cyan, Magenta, Yellow, Black) inks form the foundation of color printing. These four colors combine to create the full spectrum of printable colors. Here’s what you need to know:

- Price range: $50-200 per liter depending on quality and source

- Coverage: 1 liter covers approximately 70-125 square meters at standard resolution

- Usage pattern: Black and cyan typically deplete fastest; yellow often lasts longest

- Quality impact: Higher quality inks produce more vibrant colors and better UV resistance

White Ink: The Expensive Essential

White ink deserves special attention because it’s typically 50-100% more expensive than color inks and consumed in larger quantities. You need white ink for:

- Printing on dark or black substrates (creates opaque base layer)

- Transparent materials like acrylic and glass

- Creating spot whites and highlights

- Building texture and 3D effects (multiple layers)

White Ink Cost Impact: When printing full-coverage white underbase on dark materials, your white ink consumption can exceed your total CMYK consumption. A design that costs $0.50 in CMYK might cost $1.50+ when you add a white base layer.

Varnish & Specialty Inks

Varnish (clear gloss or matte) adds protection and visual effects to prints. While optional, it can justify premium pricing for finished products:

- Gloss varnish: Creates shiny, eye-catching finish; adds scratch resistance

- Matte varnish: Sophisticated, non-reflective finish; popular for premium products

- Spot varnish: Selective application creates texture contrast and 3D effects

- Textured varnish: Multiple layers build raised tactile effects

How to Calculate Your True Ink Cost Per Print

Understanding your actual cost per print is crucial for pricing products profitably. Let’s walk through the calculation step by step.

The Basic Formula

Ink Cost Per Square Meter = (Ink Price Per Liter) ÷ (Coverage Per Liter)

Standard Coverage Rates

| Print Resolution | Coverage (m²/Liter) | Ink Consumption |

| Draft/Low (720 dpi) | 100-125 m² | 8-10 ml/m² |

| Standard (1080 dpi) | 70-100 m² | 10-14 ml/m² |

| High Quality (1440 dpi) | 50-70 m² | 14-20 ml/m² |

| Photo/Maximum (2880 dpi) | 35-50 m² | 20-28 ml/m² |

Real-World Cost Calculations

Example 1: Phone Case (Small Item)

Product specs: Phone case print area = 0.02 m² (approximately 60mm x 110mm)

- Ink price: $70/liter (quality third-party ink)

- Coverage: 100 m²/liter at standard resolution

- Cost per m²: $70 ÷ 100 = $0.70/m²

- Cost per phone case: $0.70 × 0.02 = $0.014 (about 1.4 cents)

Result: Ink cost per phone case = approximately $0.01-0.02. With labor, electricity, and blank case costs, total production cost is typically $0.04-0.05 per case.

Example 2: Custom Tumbler (Cylindrical)

Product specs: 20oz tumbler, full wrap print area = 0.06 m²

- CMYK ink cost: $0.70/m² × 0.06 = $0.042

- White ink (if needed): $1.20/m² × 0.06 = $0.072

- Varnish layer: $0.80/m² × 0.06 = $0.048

- Total ink cost: $0.042 + $0.072 + $0.048 = $0.162

Result: Ink cost per tumbler = approximately $0.16-0.25 depending on design complexity and ink quality. Total production cost with blank tumbler ($5-6) runs $6-8 per unit.

Example 3: Large Format Sign (2m × 1m)

Product specs: PVC sign board, 2 square meters

- CMYK at high quality (1440 dpi): $1.00/m² × 2 = $2.00

- White base layer: $1.50/m² × 2 = $3.00

- Protective varnish: $1.00/m² × 2 = $2.00

- Total ink cost: $2.00 + $3.00 + $2.00 = $7.00

Result: Ink cost for 2m² sign = approximately $7-10. Total production cost with substrate ($10-15) and labor ($5-10) runs $25-35 per sign.

Hidden Ink Costs You Need to Account For

The ink cost calculations above only cover actual printing. Several other factors consume ink that you need to factor into your total cost of ownership:

1. Print Head Cleaning & Maintenance

UV printers require regular cleaning cycles to maintain print quality and prevent clogged nozzles. Each cleaning cycle consumes ink:

- Standard cleaning: 4ml per print head (8ml for dual-head systems)

- Frequency: Every 2 square meters of printing (varies by printer)

- Daily startup purge: 10-20ml depending on overnight conditions

- Estimated additional cost: $0.15-0.50 per square meter printed

2. Test Prints & Color Calibration

- Nozzle check patterns before production runs

- Color calibration test prints for color-critical work

- Material test prints for new substrates

- Estimated cost: $5-15 per production day

3. Ink Expiration & Waste

- Shelf life: UV ink typically expires 12-24 months from manufacture

- White ink settling: Requires regular agitation; settled ink may be unusable

- Cartridge residue: 5-10% of ink in cartridges may be unreachable

- Estimated waste: 5-15% of total ink purchased

Complete Ink Cost Summary

| Cost Component | Low Estimate | High Estimate |

| CMYK printing ink (per m²) | $0.30 | $1.00 |

| White ink base layer (per m²) | $0.80 | $1.80 |

| Varnish layer (per m²) | $0.50 | $1.20 |

| Maintenance/cleaning overhead (per m²) | $0.15 | $0.50 |

| TOTAL (CMYK only) | $0.45/m² | $1.50/m² |

| TOTAL (with white + varnish) | $1.75/m² | $4.50/m² |

OEM vs Third-Party Inks: What’s the Real Difference?

One of the biggest decisions affecting your ink budget is whether to use manufacturer (OEM) inks or third-party alternatives. Here’s an honest comparison:

OEM/Manufacturer Inks

- Price: $150-250 per liter (2-3x more expensive)

- Pros: Guaranteed compatibility, consistent quality, warranty protection, technical support

- Cons: Significantly higher cost, may lock you into specific suppliers

- Best for: High-value production work, color-critical applications, businesses prioritizing support over savings

Quality Third-Party Inks

- Price: $50-100 per liter (50-70% savings)

- Pros: Significant cost savings, many reputable brands available, often comparable quality

- Cons: May void warranty, quality varies by supplier, requires testing

- Best for: High-volume production, cost-conscious businesses, experienced operators

Cost Comparison: A business printing 500 m²/month would spend approximately $750-1,000 on quality third-party inks vs $1,500-2,500 on OEM inks — a potential savings of $9,000-18,000 per year.

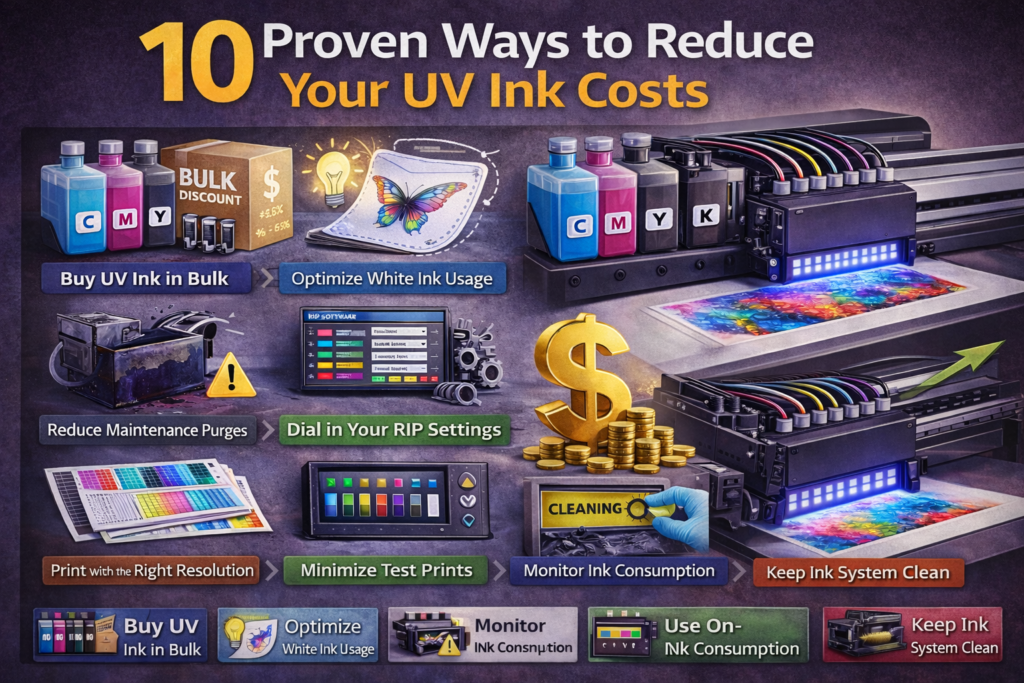

10 Proven Ways to Reduce Your UV Ink Costs

1. Buy Ink in Bulk

Purchasing larger quantities (5L or 10L containers vs 1L bottles) typically saves 15-30% on ink costs. However, only buy what you’ll use within the ink’s shelf life to avoid waste from expired ink.

2. Optimize Print Resolution

Not every job requires maximum resolution. Using 720 dpi for signage instead of 1440 dpi can reduce ink consumption by 40-50% with minimal visible quality difference at normal viewing distances.

3. Minimize White Ink Usage

- Use white substrates when possible to eliminate white underbase

- Use “smart white” settings that only print white where colors require it

- Pre-coated or pre-primed substrates can reduce white ink needs

- Optimize white layer density — often 80% coverage works as well as 100%

4. Maintain Your Printer Properly

A well-maintained printer consumes less ink on cleaning cycles and produces fewer failed prints. Schedule quarterly deep maintenance to extend print head life and reduce ink waste by up to 40%.

5. Use Color Management Software

Proper ICC profiles and RIP software optimization can reduce ink consumption by 10-20% while maintaining color accuracy. Many operators waste ink through poor color management settings.

6. Batch Similar Jobs Together

Running similar colored jobs consecutively reduces the cleaning cycles needed between jobs. Group jobs by color profile and substrate type to minimize wasted ink during transitions.

7. Nest Designs Efficiently

Use RIP software to automatically arrange multiple designs on substrates, minimizing wasted space. Efficient nesting can reduce substrate waste by 15-25% and proportionally reduces ink usage.

8. Store Ink Properly

- Keep ink at recommended temperature (typically 59-77°F / 15-25°C)

- Store away from direct sunlight

- Shake white ink regularly to prevent settling

- Use FIFO (first in, first out) inventory rotation

9. Negotiate with Suppliers

Build relationships with ink suppliers for better pricing. Volume commitments, annual contracts, and loyalty programs can unlock 10-20% additional discounts beyond list pricing.

10. Track Your Ink Usage

Maintain detailed records of ink consumption per job type. This data helps identify waste, optimize pricing, and make better purchasing decisions. Many businesses discover 20-30% savings opportunities through tracking.

Monthly Ink Budget Planning Guide

Planning your monthly ink budget helps prevent cash flow surprises and enables bulk purchasing for better pricing. Here’s a framework based on production volume:

| Business Size | Monthly Print Volume | Est. Ink Consumption | Monthly Ink Budget |

| Hobby/Side Business | 10-50 m² | 0.5-2 liters | $70-200 |

| Small Business | 50-200 m² | 2-8 liters | $200-600 |

| Medium Business | 200-500 m² | 8-20 liters | $600-1,500 |

| High Volume Production | 500+ m² | 20+ liters | $1,500+ |

Make Every Drop Count

Understanding and optimizing your UV printer ink costs is one of the most impactful things you can do for your printing business’s profitability. The difference between a well-optimized operation and one that ignores ink efficiency can be tens of thousands of dollars per year.

Key takeaways to remember:

- Ink costs $0.30-1.50 per square meter for CMYK; add $0.80-2.00 for white underbase

- Quality third-party inks can save 50-70% vs OEM without sacrificing quality

- Hidden costs (maintenance, waste, test prints) add 15-30% to base ink costs

- Bulk purchasing, proper maintenance, and smart settings can cut costs by 15-30%

- Track your usage to identify optimization opportunities

Ready to start your UV printing business or upgrade your equipment? Explore our UV printer collection to find machines optimized for efficient ink usage and low operating costs.

Frequently Asked Questions

How much does a full set of UV inks cost?

A complete CMYK+W+V (6-color) ink set costs approximately $340-1,100 for third-party inks or $900-1,500 for OEM inks. This typically provides enough ink for 500-1,000+ square meters of printing depending on coverage.

Why is white ink so expensive?

White UV ink requires titanium dioxide pigments for opacity, which are more expensive than color pigments. Additionally, white ink requires special formulation to prevent settling and maintain consistent coverage, adding to production costs.

How long does UV ink last before expiring?

Most UV inks have a shelf life of 12-24 months from manufacture when stored properly. White ink may have shorter life due to pigment settling. Always check manufacture dates and store ink at recommended temperatures away from sunlight.

Will using third-party ink void my printer warranty?

Many manufacturers state that using non-OEM inks voids warranty. However, in practice, warranty issues typically only arise if the third-party ink directly causes damage. Quality third-party inks from reputable suppliers rarely cause problems. Weigh the savings against warranty risk for your situation.

How can I reduce white ink consumption?

Use white or light-colored substrates when possible, enable “smart white” settings in your RIP software, reduce white layer density to 70-80% for adequate coverage, and consider pre-coated substrates that require less white underbase.

What’s the ink cost per phone case?

At typical rates, the ink cost per phone case is approximately $0.01-0.03 for CMYK only, or $0.03-0.06 with white underbase. This makes phone cases one of the most profitable UV printing products with minimal ink investment per unit.