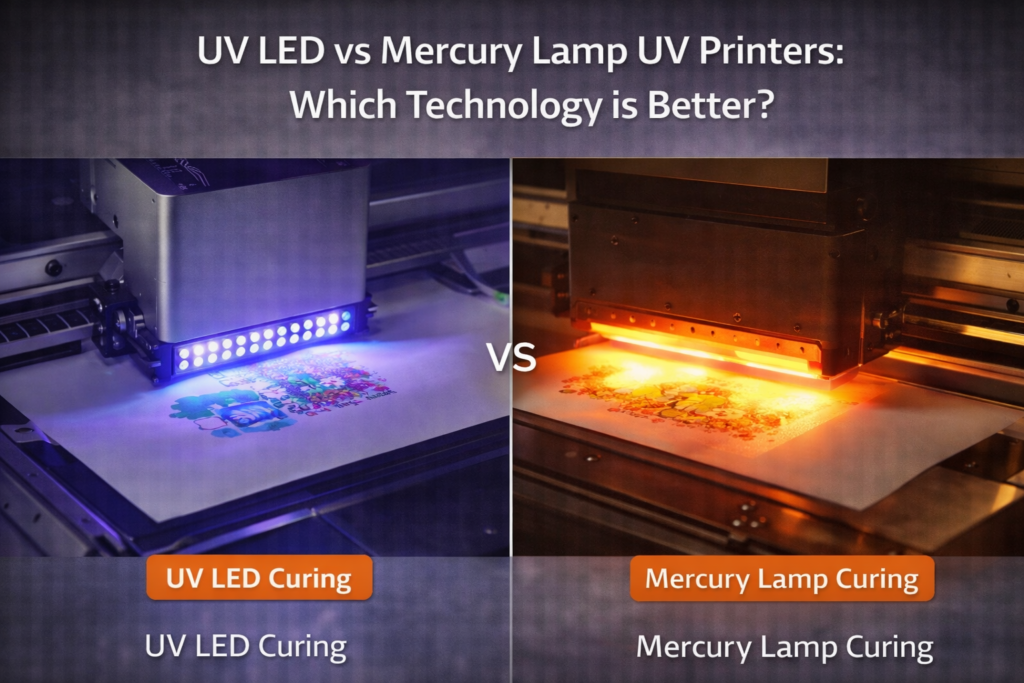

Complete comparison of UV LED and mercury lamp curing technologies. Learn the differences in lifespan, energy consumption, heat output, cost, and which is right for your UV printing business.

Quick Answer: UV LED technology is better for most modern UV printing applications. LED systems last 10,000-30,000+ hours vs 1,000-2,000 hours for mercury lamps, consume 50-80% less energy, produce minimal heat (safe for heat-sensitive materials), require no warm-up time, and are mercury-free. While UV LED printers have higher upfront costs, their lower operating costs typically deliver ROI within 1-2 years for regular use.

When shopping for a UV printer, one of the most important specifications you’ll encounter is the curing technology: UV LED or traditional mercury lamp. This choice significantly impacts your operating costs, print quality, material compatibility, and environmental footprint.

In this comprehensive guide, we’ll break down every difference between these two UV curing technologies, helping you make an informed decision based on your specific business needs.

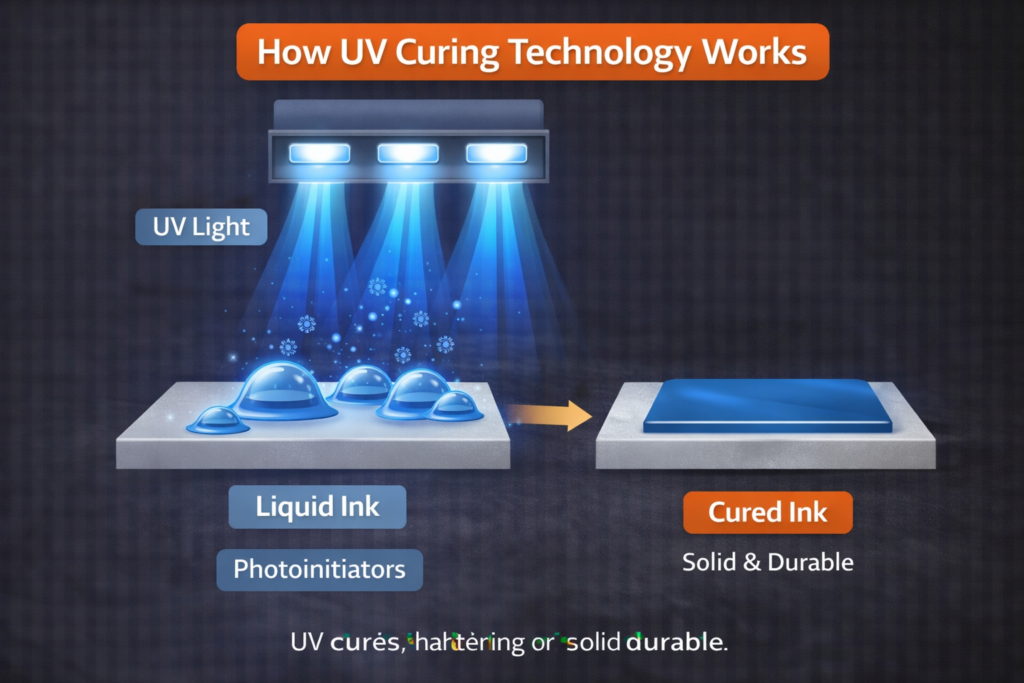

How UV Curing Technology Works

Before comparing the two technologies, it’s helpful to understand what UV curing actually does. UV curing is a photochemical process where ultraviolet light triggers a reaction in specially formulated inks, causing them to instantly harden (cure) on the substrate surface.

UV-curable inks contain photoinitiators — chemical compounds that absorb UV light energy and initiate polymerization. When exposed to the correct UV wavelength, these photoinitiators trigger a chain reaction that converts the liquid ink into a solid, durable finish within milliseconds.

The key difference between UV LED and mercury lamp curing lies in how they produce the UV light that triggers this reaction — and this difference has major implications for performance, cost, and capability.

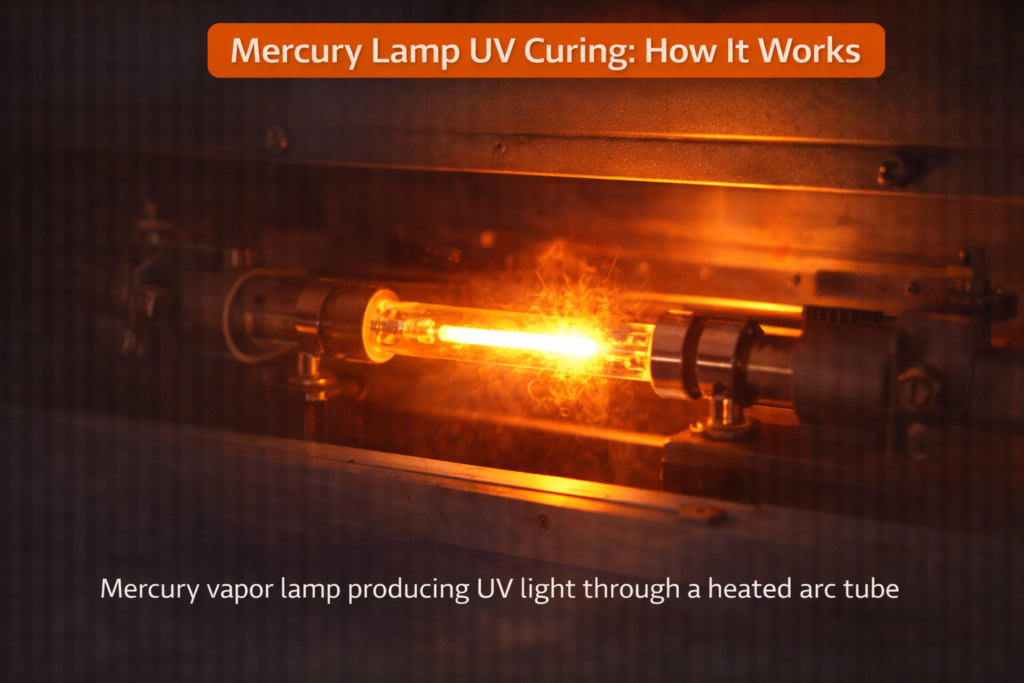

Mercury Lamp UV Curing: The Traditional Approach

Mercury vapor lamps have been the industry standard for UV curing for decades. These lamps work by heating mercury until it vaporizes, then passing an electrical current through the vapor to produce UV light.

How Mercury Lamps Work

Inside a mercury lamp, an electrical arc passes through mercury vapor contained in a quartz tube. This excites the mercury atoms, causing them to emit radiation across a broad spectrum — including UVA (315-400nm), UVB (280-315nm), UVC (100-280nm), visible light, and infrared (heat).

Mercury Lamp Specifications

| Specification | Mercury Lamp |

| Wavelength Output | Broad spectrum: 200-450nm (UVC, UVB, UVA) |

| Typical Lifespan | 1,000-2,000 hours |

| Operating Temperature | 600-800°C (arc tube); 100°C+ (surface) |

| Warm-up Time Required | Yes (5-15 minutes) |

| Energy Efficiency | ~20-30% of energy becomes UV light |

| Ozone Production | Yes (requires ventilation) |

| Contains Hazardous Materials | Yes (mercury) |

Mercury Lamp Advantages

- Broad spectrum output: Works with a wide range of UV-curable inks and coatings

- Deep curing capability: Better penetration for thick coatings and pigmented inks

- Lower initial cost: Mercury lamp systems typically cost less upfront

- Mature technology: Proven reliability with decades of industry use

- Ink compatibility: Compatible with all traditional UV-curable formulations

Mercury Lamp Disadvantages

- Short lifespan: Requires replacement every 1,000-2,000 hours of operation

- High energy consumption: Only 20-30% of energy produces useful UV light

- Excessive heat: Can damage heat-sensitive substrates like thin plastics

- Warm-up time: 5-15 minutes before reaching optimal output

- Ozone production: UVC wavelengths create ozone, requiring ventilation systems

- Environmental concerns: Contains mercury; requires special disposal procedures

- Output degradation: UV output decreases over lamp life, affecting cure consistency

UV LED Curing: The Modern Standard

UV LED (Light Emitting Diode) technology represents a fundamental shift in UV curing. Instead of heating mercury vapor, LED systems use semiconductor technology to produce UV light directly from electrical current — similar to how visible LEDs work in modern lighting.

How UV LEDs Work

UV LEDs use semiconductor materials that emit photons when electrical current passes through them. By selecting specific semiconductor compositions, manufacturers can produce LEDs that emit precise UV wavelengths — typically 365nm, 385nm, 395nm, or 405nm for printing applications.

UV LED Specifications

| Specification | UV LED |

| Wavelength Output | Narrow band: 365nm, 385nm, 395nm, or 405nm |

| Typical Lifespan | 10,000-30,000+ hours (up to 60,000) |

| Operating Temperature | 40-80°C (104-176°F) |

| Warm-up Time Required | No (instant on/off) |

| Energy Efficiency | ~40-50% of energy becomes UV light |

| Ozone Production | No |

| Contains Hazardous Materials | No |

UV LED Advantages

- Exceptional lifespan: 10,000-30,000+ hours vs 1,000-2,000 for mercury lamps

- Energy efficiency: Consumes 50-80% less electricity than mercury systems

- Low heat output: Safe for heat-sensitive materials like thin plastics, films, paper

- Instant on/off: No warm-up or cool-down time; immediate productivity

- Consistent output: Maintains stable UV intensity throughout lifespan

- Environmentally friendly: Mercury-free; no ozone production; no hazardous waste

- Lower maintenance: Minimal maintenance costs; no lamp replacement for years

- Compact design: Smaller form factor; no bulky cooling systems required

- Precise control: Can be dimmed and controlled with greater precision

UV LED Disadvantages

- Higher initial cost: UV LED printers typically cost more upfront

- Narrow wavelength: Requires LED-specific or LED-compatible inks

- Curing depth limitations: May struggle with very thick coatings or heavily pigmented inks

- Ink cost: LED-optimized inks may cost slightly more in some cases

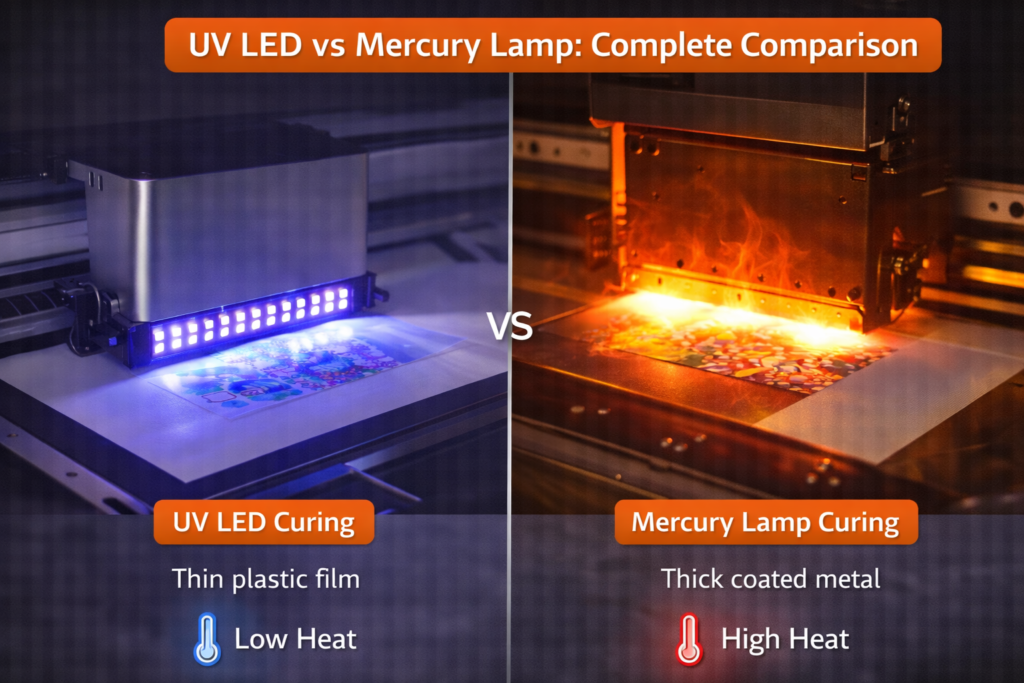

UV LED vs Mercury Lamp: Complete Comparison

| Factor | UV LED | Mercury Lamp |

| Lamp Lifespan | 10,000-30,000+ hrs | 1,000-2,000 hrs |

| Energy Consumption | 50-80% less | High |

| Heat Output | Low (40-80°C) | Very High (100°C+) |

| Warm-up Time | None (instant) | 5-15 minutes |

| Initial Cost | Higher | Lower |

| Operating Cost | Much Lower | Higher |

| Maintenance Cost | Minimal | Frequent lamp replacement |

| Heat-Sensitive Materials | Excellent | Poor (may damage) |

| Ozone Production | None | Yes (ventilation needed) |

| Environmental Impact | Eco-friendly | Contains mercury |

| Thick Coating Cure | Limited | Better |

| Output Consistency | Stable throughout life | Degrades over time |

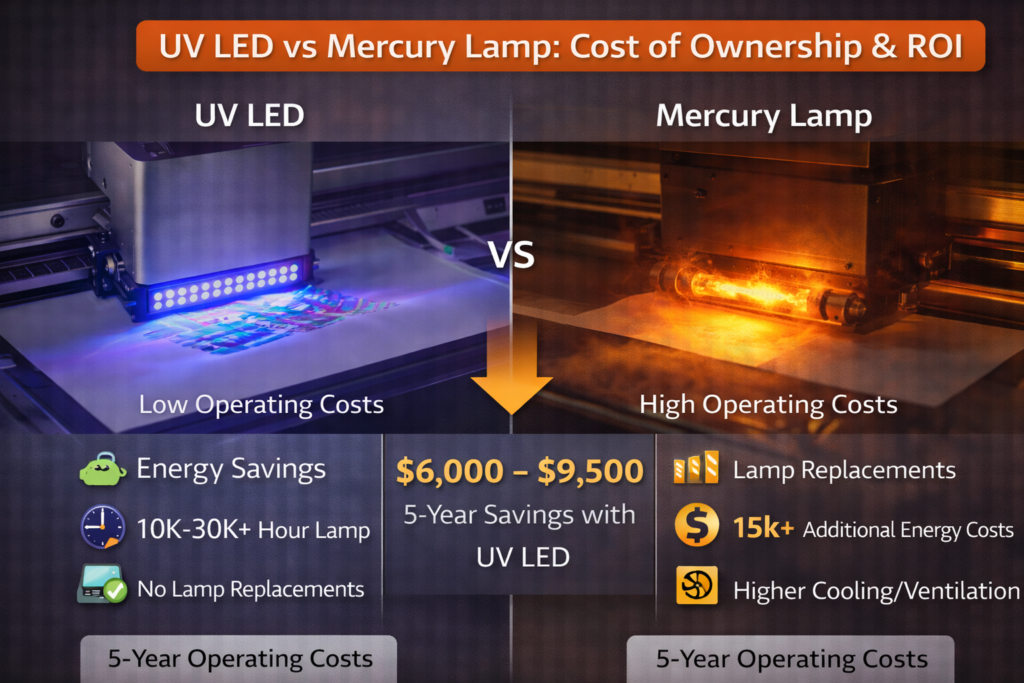

Total Cost of Ownership: The Real Numbers

While UV LED printers have higher upfront costs, the total cost of ownership over 3-5 years often favors LED technology significantly. Let’s break down the numbers:

5-Year Cost Comparison (Based on 2,000 hours/year operation)

| Cost Category | UV LED | Mercury Lamp |

| Printer Price Premium | +$2,000-5,000 | $0 (baseline) |

| Lamp Replacements (5 yrs) | $0 | $3,000-6,000 |

| Energy Costs (5 yrs) | $1,500-2,500 | $5,000-8,000 |

| Cooling/Ventilation | $0-500 | $1,000-2,000 |

| Downtime Costs | Minimal | $500-1,500 |

| 5-Year Total | $3,500-8,000 | $9,500-17,500 |

| Potential 5-Year Savings | $6,000-9,500 with UV LED | |

Key Insight: For businesses operating 2,000+ hours annually, UV LED systems typically pay for their price premium within 12-24 months through energy savings and eliminated lamp replacement costs.

When to Choose UV LED vs Mercury Lamp

Choose UV LED Technology When:

- You print on heat-sensitive materials (thin plastics, films, paper, electronics)

- Energy costs are significant in your region

- You need instant on/off capability for short runs or frequent job changes

- Environmental compliance and sustainability are priorities

- You want minimal maintenance and maximum uptime

- You’re building a new operation and can invest in long-term savings

- You operate in a workspace without extensive ventilation

- Consistent cure quality matters for your products

Choose Mercury Lamp Technology When:

- You have a limited initial budget

- You need to cure very thick coatings (industrial applications)

- You’re using legacy UV-curable formulations not compatible with LED

- Your existing equipment uses mercury and replacement isn’t practical

- You operate very low hours where LED ROI won’t materialize

The Future: Why Industry is Moving to UV LED

The printing industry is clearly trending toward UV LED technology. Several factors are accelerating this transition:

- Regulatory pressure: The Minamata Convention and other regulations are restricting mercury use globally

- LED technology improvements: UV LED output increases approximately 12% annually, closing the power gap

- Ink formulation advances: LED-optimized inks now match or exceed traditional UV ink performance

- Sustainability requirements: Brands increasingly require eco-friendly manufacturing from suppliers

- Cost curve: LED system prices continue falling as production scales up

- New applications: LED’s low heat enables printing on materials impossible with mercury lamps

Most printer manufacturers now offer UV LED as their primary or only option for new equipment. While mercury lamp systems will remain available for specialized applications, UV LED has become the modern standard for professional UV printing.

Making Your Decision

For most modern UV printing businesses, UV LED technology is the clear winner. The combination of dramatically lower operating costs, environmental benefits, material versatility, and reduced maintenance makes LED the smart long-term investment — even with higher upfront costs.

Mercury lamp systems still have their place for specific applications requiring deep-cure capability or for businesses with existing mercury-based infrastructure. However, for new equipment purchases, UV LED is almost always the recommended choice.

Ready to explore UV LED printing for your business? Browse our UV printer collection — all featuring modern UV LED curing technology for maximum efficiency and versatility.

Frequently Asked Questions

Can I use regular UV ink with a UV LED printer?

Not always. UV LED printers require inks formulated for the specific LED wavelength (typically 385nm or 395nm). Many ink manufacturers now offer “LED-compatible” or “hybrid” inks that work with both technologies, but always verify compatibility before use.

How long do UV LED lamps actually last?

Quality UV LED systems last 10,000-30,000 hours, with some manufacturers claiming up to 60,000 hours when properly maintained. At 2,000 hours of annual use, that’s 5-15+ years without lamp replacement.

Is UV LED curing as strong as mercury lamp curing?

For most printing applications, yes. Modern UV LED systems provide excellent cure quality for standard ink film thicknesses. Mercury lamps may still have advantages for very thick coatings or specialized industrial applications requiring deep penetration.

Can I retrofit my mercury lamp printer to UV LED?

Many manufacturers offer retrofit kits to convert mercury lamp systems to UV LED. However, you’ll also need to switch to LED-compatible inks. Consult your printer manufacturer to determine if retrofit is possible and cost-effective for your model.

Why do UV LED printers cost more?

UV LED technology uses semiconductor manufacturing processes that are more expensive than traditional lamp production. However, LED costs continue to decrease as production scales up, and the total cost of ownership over the printer’s lifetime is typically lower than mercury lamp systems.

Are mercury lamp UV printers being phased out?

While not immediately disappearing, the industry trend strongly favors UV LED. Regulatory restrictions on mercury (like the Minamata Convention), combined with LED’s superior economics and environmental profile, mean most new printer development focuses on LED technology. Mercury systems will remain available for legacy and specialized applications.