UV DTF vs Regular DTF: Key Differences & Which One to Choose

Digital printing technologies continue to evolve rapidly, and two of the most talked-about methods in the textile and customization world are UV DTF (UV Direct-to-Film) and Regular DTF (Direct-to-Film) printing. Both offer excellent print quality and versatile application, but understanding their differences is crucial for businesses, print shops, and professionals looking to invest wisely.

In this article, we’ll dive deep into:

- What UV DTF and Regular DTF are

- How they compare technically and in real-world use

- Pros and cons of each technology

- Best use cases

- Purchasing and workflow considerations

- Which one you should choose based on your goals

Let’s begin.

1. What Is DTF Printing? – A Quick Primer

DTF (Direct-to-Film) printing is a technique where designs are printed onto specialized film and then transferred onto substrates like fabric, wood, metal, or plastics using heat and pressure. This method has gained popularity because it’s:

- Cost-efficient

- High-quality

- Easy to integrate into production workflows

- Suitable for small to large print runs

Traditional DTF uses solvent-based or water-based inks and requires pretreatment powders to ensure adhesion and durability.

2. What Is UV DTF Printing?

UV DTF uses ultraviolet (UV) curable inks in place of the typical solvent or water-based inks used in regular DTF. After printing, UV lamps instantly cure (dry) the ink, which creates a finished print that’s ready for transfer.

The advantages of using UV ink include:

- Excellent durability

- Wider color gamut

- Resistance to scratching and fading

- Smooth, vibrant prints

UV DTF combines the flexibility of DTF with the rugged performance of UV ink systems.

This technique is often implemented on advanced systems like the UV printer 9060 or other UV printers with film handling capabilities.

3. Regular DTF Printing Explained

Regular DTF remains one of the most accessible and cost-effective methods for garment and product decoration. In this process:

- Design is printed directly onto film using water-based or pigment inks

- A hot melt adhesive powder is applied

- The film is cured

- The design is heat-pressed onto the substrate

This method works well with cotton, polyester blends, leather, and even some coated surfaces.

4. UV DTF vs Regular DTF — Key Technical Differences

| Feature | UV DTF | Regular DTF |

|---|---|---|

| Ink Type | UV curable ink | Water/pigment/solvent ink |

| Drying/Curing | Instant UV cure | Heat or air dry |

| Print Durability | Very high (scrub & fade resistant) | Good, dependent on post-processing |

| Color Vividness | Excellent | Good to very good |

| Print Feel | Slightly firmer | Softer hand feel |

| Substrate Compatibility | Very broad (even rigid substrates) | Best for flexible textiles |

| Equipment Cost | Higher | Lower to mid-range |

| Maintenance | Higher | Moderate |

5. Why UV Ink Is a Game-Changer

UV inks are unique because they cure instantly when exposed to ultraviolet light. This gives several advantages:

a. Instant Curing

Unlike water-based inks that require time to dry, UV inks are cured right after printing, reducing workflow bottlenecks.

b. Superior Outdoor Performance

UV prints are less prone to fading and weather degradation, making them perfect for outdoor signage or decorated products that see heavy use.

c. Versatility Across Substrates

UV DTF works well on:

- Fabrics

- Metals

- Plastics

- Ceramic mugs and tumblers

- Hard signage

- Custom promotional products

Whether you have a flatbed cylindrical printer or a more advanced 360 rotary UV printer for tumblers and bottles, UV inks open up multi-surface printing options.

6. How Regular DTF Still Holds Value

Regular DTF printing remains extremely popular because of its simplicity and cost effectiveness:

a. Lower Equipment Cost

Traditional DTF printers are significantly cheaper than UV systems, making them ideal for small to medium startups.

b. Easier Consumable Sourcing

Inks, films, and powders are widely available.

c. Soft Hand Feel

Since the transfer printing layer is thinner, clothes and garments feel softer.

d. Great Color Range

Pigment and water-based inks still deliver impressive output, especially on textiles.

7. Print Quality and Durability

UV DTF

- Excellent scratch, wash, and fade resistance

- Vibrant, high-contrast images

- Less prone to color bleed

Regular DTF

- Very good durability (especially with correct curing and pressing)

- Wash-resistant for garments

- Slightly softer results

In terms of pure durability and weather resistance, UV DTF outperforms standard DTF, particularly for product decoration and outdoor signage.

8. Workflow & Production Speed

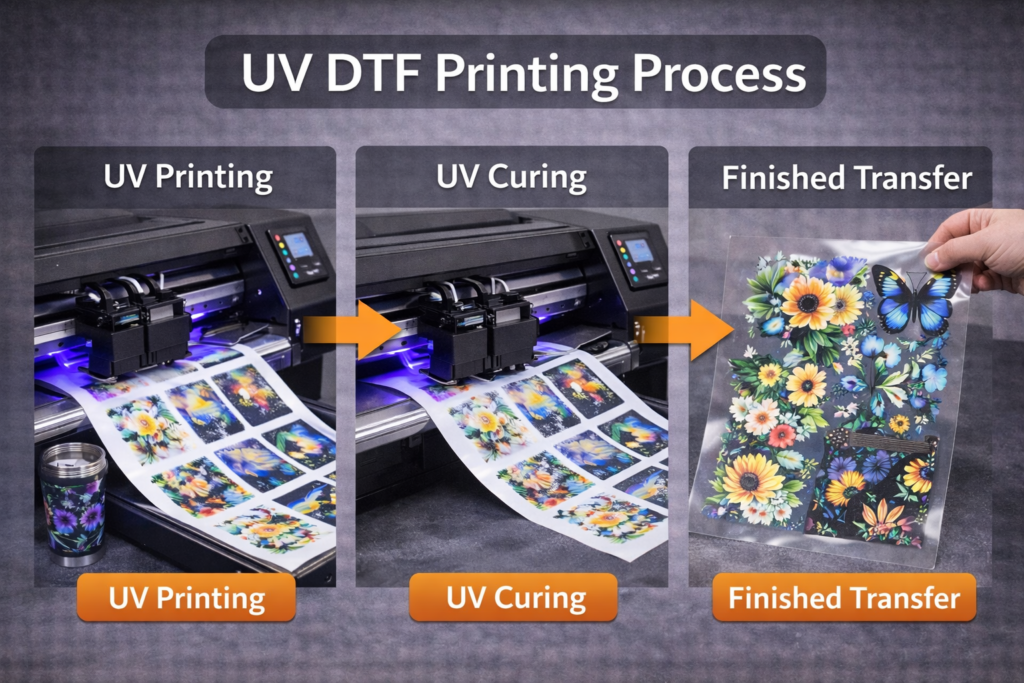

UV DTF Workflow

- Design output

- UV printing

- UV curing

- Heat press transfer

Curing is instant, which can speed up the workflow — especially if producing in high volume.

Regular DTF Workflow

- Design output

- Print to film

- Powder application

- Heat curing / drying

- Heat press transfer

This workflow can be slightly longer due to drying and curing time — though modern equipment has significantly optimized this.

9. Equipment Costs — What to Expect

UV Systems

Investing in UV DTF setups generally requires higher capital because you need:

- UV-capable printer hardware

- Integrated UV LED curing lamps

- More complex drying & cooling systems

For example, professional models like the UV printer 9060 offer industrial reliability but at a premium.

Regular DTF Printers

Entry-level and mid-range DTF printers are more accessible in pricing, making them the go-to choice for new print shops.

10. Substrates and Applications

| Substrate | UV DTF | Regular DTF |

|---|---|---|

| Cotton fabrics | ✔️ | ✔️ |

| Polyester | ✔️ | ✔️ |

| Leather | ✔️ | ✔️ |

| Ceramics | ✔️ | ❌ |

| Metal | ✔️ | ❌ |

| Plastic items | ✔️ | Limited |

| Glass & acrylic | ✔️ | ❌ |

As you can see, UV DTF offers broader substrate compatibility — perfect for businesses handling a variety of products.

11. When to Choose Regular DTF First

You should strongly consider Regular DTF if:

- You’re starting a print business with limited initial investment

- Your primary focus is garment printing

- You want softer hand feel for T-shirts and apparel

- Consumable cost must stay low

Regular DTF is reliable, affordable, and excellent for standard textile work.

12. When UV DTF Becomes the Better Option

Choose UV DTF if:

- You print on rigid or non-textile surfaces

- You need maximum durability

- Your business requires broader product offerings

- You want very high-quality graphics

- You’re producing tumblers, bottles, ceramics, gifts, or promotional items

In this scenario, pairing a UV-capable system with rotary or cylindrical accessories significantly increases your product range — for example, a 360 rotary UV printer or a cylinder UV printer can print full wrap designs on curved substrates.

13. Hybrid and Visual Positioning UV Printers

As technology grows, so do hybrid options. Systems like hybrid UV printers and Visual Positioning UV Printers bring automation and precision to complex jobs:

Hybrid UV Printers

- Combine flat and roll printing

- Ideal for mix jobs (fabric + hard signage)

- More flexible workflow

Visual Positioning UV Printers

- Use cameras and sensors

- Auto-align prints to irregular shapes

- Perfect when precision placement matters

These advanced tools are popular in established print houses offering highly customized products.

14. Heat Pressing — A Shared Requirement

Regardless of whether you use Regular or UV DTF, heat pressing is essential for transferring the film design onto the final product. The effectiveness of this step significantly affects wash-fastness, adhesion, and overall quality.

Tips for best results:

- Use correct temperature (typically 150–165°C for textiles)

- Adjust pressure based on substrate

- Ensure full curing — especially with regular DTF

Proper post-press care is often the difference between mediocre and premium results.

15. Cost of Consumables

Regular DTF

- Film

- Inks

- Powder adhesive

- Pretreatment

→ Generally economical

UV DTF

- UV curable inks (more expensive)

- Film

- Possible coatings

→ Higher consumable cost, but balanced by durability and product value

Your pricing model should consider these differences to maintain profitability.

16. Ease of Maintenance

Regular DTF setups tend to be:

- Easier to clean

- Less demanding in maintenance

- More forgiving with ink handling

UV printers require:

- UV lamp maintenance

- Specialized cleaning cycles

- Routine checks of curing systems

If you’re new to UV systems, plan for training and setup support.

17. Environmental & Safety Considerations

UV inks are generally less volatile than solvent inks, and VOC emissions are minimal. However, you must:

- Ensure proper ventilation

- Wear PPE during maintenance

- Follow safety guidelines for UV exposure

Regular DTF with solvent inks must be carefully handled due to fumes and proper disposal.

18. Market Trends & ROI

Industry analysts show a growing preference for UV-based printing due to its versatility and premium finish. However, Regular DTF remains a strong contender for textile-only shops.

From an investment perspective:

- UV DTF yields higher ROI on diversified product offerings

- Regular DTF gives quick returns with lower risk

Choosing wisely depends on your market strategy.

19. Comparing Print Examples

| Print Type | Durability | Vibrancy | Hand Feel | Outdoor Use |

|---|---|---|---|---|

| UV DTF | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Regular DTF | ⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ |

UV DTF clearly excels in outdoor durability and color stability — important for promotional products, signage, mugs, tumblers, gifts, and branded merchandise.

20. Real-World Use Cases

Regular DTF

✔ Custom T-shirts

✔ Promotional apparel

✔ Textile merchandise

✔ Small batch orders

UV DTF

✔ Mugs & tumblers

✔ Sign panels

✔ Acrylic products

✔ Customized gifts

✔ Personalized tumblers via rotary printers

Integrating tools like a tumbler printer with your UV DTF setup can significantly expand your revenue streams.

21. Training and Skill Requirements

Both systems require training:

- Regular DTF: easier learning curve

- UV DTF: needs understanding of curing dynamics and ink behavior

Many manufacturers provide onboarding support — always take advantage of this for optimal results.

22. Scalability Considerations

If you plan to scale:

- Regular DTF can scale horizontally with additional units

- UV DTF can scale by adding multifunctional tools like hybrid and rotary units

Think long-term — diversification often trumps single-product focus.

23. Which One Should You Choose?

Choose Regular DTF If:

- Your focus is garment decoration

- Your budget is limited

- You want soft hand feel designs

- You’re building a niche in apparel printing

Choose UV DTF If:

- You want to print on hard and soft substrates

- You want premium finishes and durability

- You plan to offer full product personalization

- You want rapid curing and reduced post-processing time

If your business model includes both garments and promotional items, you might benefit from a hybrid setup — combining regular DTF and UV systems for maximum flexibility.

24. Final Takeaways

Both UV DTF and Regular DTF are powerful digital printing technologies — each with its strategic advantages. Choosing between them requires careful consideration of:

- Budget

- Business goals

- Substrates you plan to print on

- Quality expectations

- Workflow and production speed

Investing in the right technology today can define your brand’s competitive edge tomorrow.

25. Start Printing Smartly

Whether you’re leaning toward Regular DTF for textiles or UV DTF for multi-substrate production, the key is matching technology to your market and customer demands.

Explore options like:

- UV printers for broad application

- UV printer 9060 for industrial-grade performance

- Cylindrical printers for bottles and mugs

- 360 rotary UV printers for full wrap printing

Each of these can power next-generation customization services.